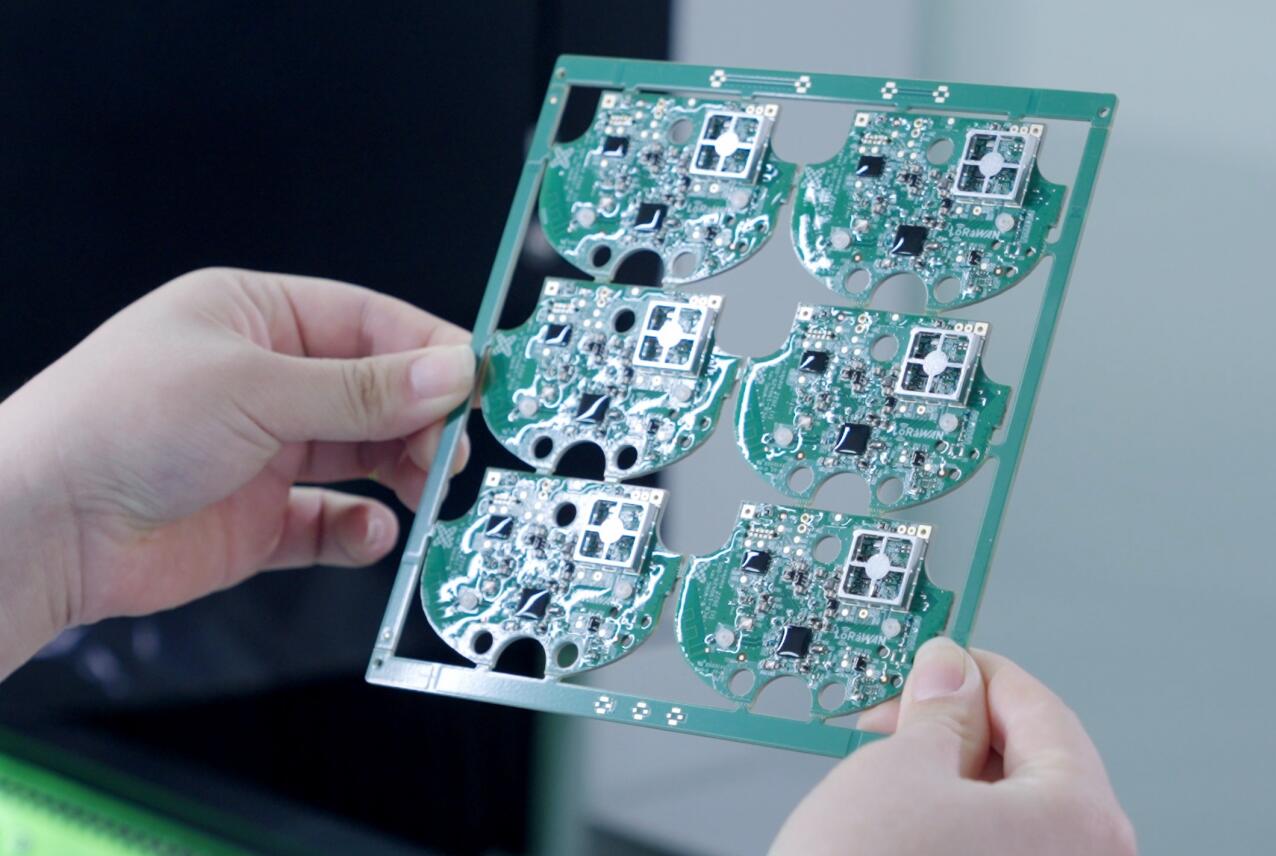

PCBA, which stands for Printed Circuit Board Assembly, is the process of assembling electronic components onto a printed circuit board. This includes soldering components such as resistors, capacitors, integrated circuits, and other electronic parts onto the board to create a functional electronic assembly.

The application of PCBA is widespread across various industries, including consumer electronics, automotive, aerospace, medical devices, telecommunications, and industrial equipment. PCBA is used in products such as smartphones, computers, automotive control systems, medical monitoring devices, and many other electronic devices that we use in our daily lives.

The importance of PCBA in a product lies in its role as the foundation of electronic devices. The quality and reliability of the PCBA directly impact the performance and longevity of the end product. A well-designed and manufactured PCBA ensures the proper functioning of the electronic device, while a poorly executed PCBA can lead to malfunctions and failures. Additionally, efficient PCBA design and manufacture can contribute to cost-effectiveness, energy efficiency, and compact product size, which are crucial factors in today's competitive market.

Our SMT workshop is equipped with two complete surface mount technology assembly lines including Automatic PCB loader, imported printers high Precision online SPI inspection Systems, Yamaha and Seamens high speed pick-and-place machines, high precision online AOI systems and a 10 zone reflow soldering oven these ensure both high performance product outcomes and efficient production processes.

We have introduced x Ray testing equipment to detect the voiding rate of BGA solder joints analyze internal displacements of PCBA and calculate the reliability of soldering based on the test data a voiding rate and chip displacement.

We emphasize meticulous control over every detail to ensure the highest standards before assembly each PCBA undergo specialized selective coding incurring for special protection rigorous functional testing is conducted using corresponding fixtures to ensure a reliable operation of the product in harsh conditions of high temperature and humidity.

Welcome to contact us if any demands or inquires.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2023 Tripath International Inc. All Rights Reserved.

- Design By BONTOP