Tripath proceed essential dimensional measurements on the plastic products to ensure the product meet design requirements.

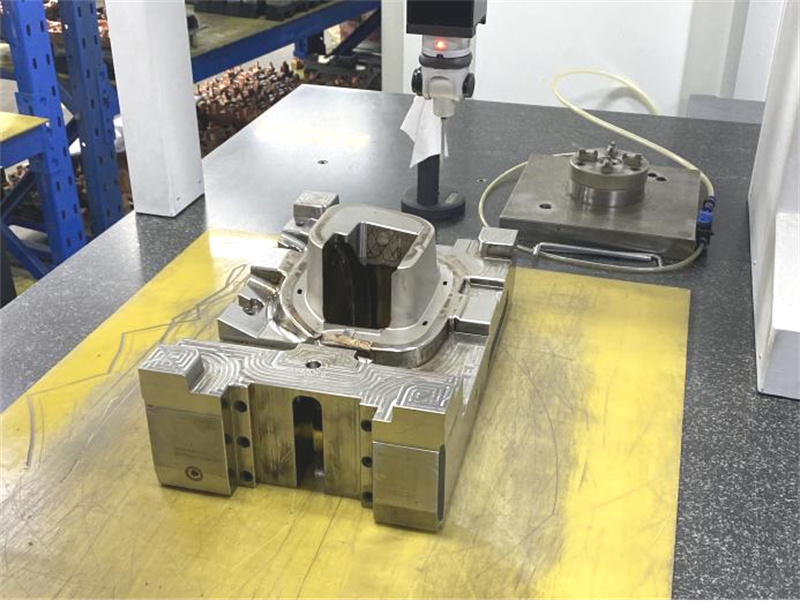

The size measurement of plastic products refers to the process of detecting and measuring the dimensions of plastic products using projection measurement or coordinate measurement techniques.

Projection measurement is a commonly used method for size detection. It projects light onto the object being measured and uses the projection and image changes of light to measure the dimensions of the object. In plastic product size measurement, light sources and cameras can be used to capture images of the object being measured, and then image processing and analysis software can be used to measure the dimensions of the object.

Coordinate measurement, on the other hand, is a more precise method for size detection. It uses three coordinate axes (X, Y, Z) to measure the three-dimensional coordinate positions of objects. In plastic product size measurement, a coordinate measuring machine can be used to measure the length, width, height, and other key dimensions of the object. The coordinate measuring machine contacts the surface of the object being measured with a probe, records the coordinates of each point, and then determines the dimensions of the object through calculation and analysis.

We use the two size measurement methods to help us ensure that the dimensions of plastic products meet design requirements, thereby improving product quality and performance.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2023 Tripath International Inc. All Rights Reserved.

- Design By BONTOP