The advocacy for green transportation and the widespread adoption of electric vehicles have driven a rapid increase in the demand for charging stations.

As more and more people choose electric vehicles as their preferred mode of environmentallytransportation, the construction of charging stations have become increasingly urgent and important.

In a recent project, we were approached by a customer who needed plastic parts designed and manufactured for their EV charging station. During the course of this project, we consistently engaged in open and frequent communication with the customer, actively discussing product functionalities and design particulars, with the ultimate goal of ensuring that the final product would align perfectly with their expectations.

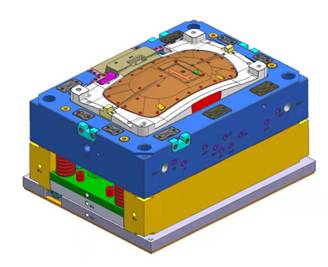

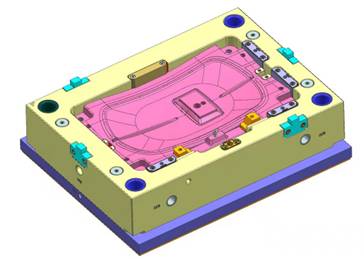

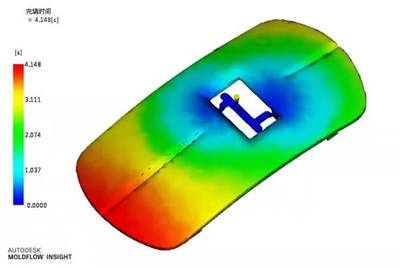

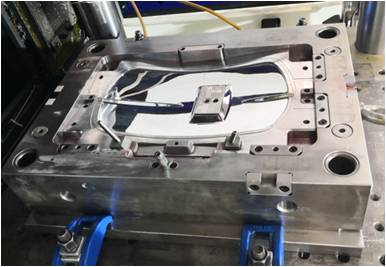

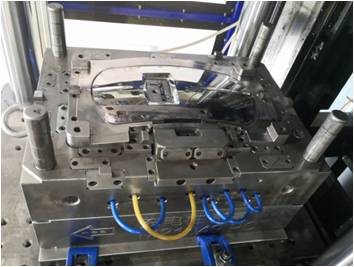

At Tripath, we possess our own mold design and manufacturing department, along with an injection molding workshop that consistently produces high-standard plastic parts. The surface of this product requires relatively high smoothness requirements, so the production of injection molds is extremely important. Our engineers analyze the mold flow when making the mold to simulate the injection molding process and verify the authenticity of the mold.

This product is used in real life and has been put into production. And now we are working with other new project with EV charger with modern design.

If you need any further information or additional inquiries, please do not hesitate to contact us. We are more than happy to assist you with your plastic part manufacturing needs.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP