Testing

-

Product dimension test

Tripath proceed essential dimensional measurements on theplastic products to ensure the product meet design requirements.

The size measurement of plastic products refers to the process of detecting and measuring the dimensions of plastic products using projection measurement or coordinate measurement techniques.Details -

Product Rohs environmental test

RoHS (Restriction of Hazardous Substances) is an environmental directive established by the European Union, aimed at limiting the content of hazardous substances used in electronic and electrical equipment to protect human health and the environment.Details -

Flame retardant test

When plastic products burn in a fire, they release toxic smoke and flames, posing a threat to people and property. In order to ensure the safety of plastic products in fires, plastic flame retardant testing is widely used to assess the flame retardant performance of plastic materials.Details -

Surface roughness test

Surface roughness tester is a special instrument used to measure the surface roughness of objects. It evaluates the smoothness or roughness of the surface by measuring and analyzing the texture, concavity, undulation and other characteristics of the surface of the object. The instrument we use uses technology optical sensors to provide accurate surface roughness parameters.Details -

Tensile strength test

Metal tensile strength testing is a commonly used material mechanics testing method used to evaluate the tensile properties of metal materials under stress. This test helps determine the strength, toughness and reliability of metallic materials.Details -

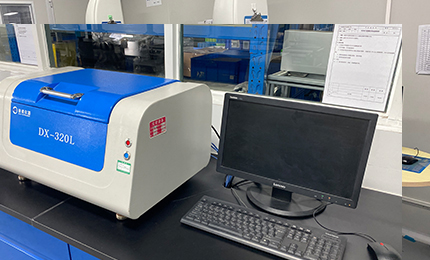

Metal element test

Metal elemental analysis testing is a method used to determine the types and quantities of elements present in a metal sample by using a spectrometer. This testing involves exposing the metal sample to high temperatures, causing it to emit specific spectral signals, which are then analyzed using a spectrometer to determine the elemental composition of the metal sample.Details -

Wear resistance test

The role of the abrasion tester is to evaluate the wear resistance of product surface coatings. During the experiment, the specimen is subjected to a certain load and rubbed against rubber and alcohol. By observing the wear effect of the specimen after a certain number of rotations, the quality and durability of the coating can be determined.Details -

Hardness test

The metal hardness tester is an instrument used to measure the hardness of metal materials. It applies a certain amount of force or pressure to the metal surface and measures the resistance of the metal material to this force to determine the hardness value. Hardness testers consist of diamond-tipped cones that create an indentation on the metal surface, and the hardness value is calculated by measuring the size or depth of the indentation.Details -

Salt spray test

Salt spray test, also known as a salt fog test or salt corrosion test, is a standardized test method used to evaluate the corrosion resistanceDetails -

Low & high temperature aging test

Low and high-temperature aging tests are processes used to evaluate the behavior of materials or products under prolonged exposure to extreme temperatures, both low and high.Details -

Water proof test

A waterproof test is a critical evaluation conducted to assess a product's ability to resist water penetration and maintain its functionality in wet conditions.Details -

Battery cycle test

A battery cycle test is a procedure used to evaluate the performance and durability of a battery by subjecting it to repeated charge and discharge cycles.Details -

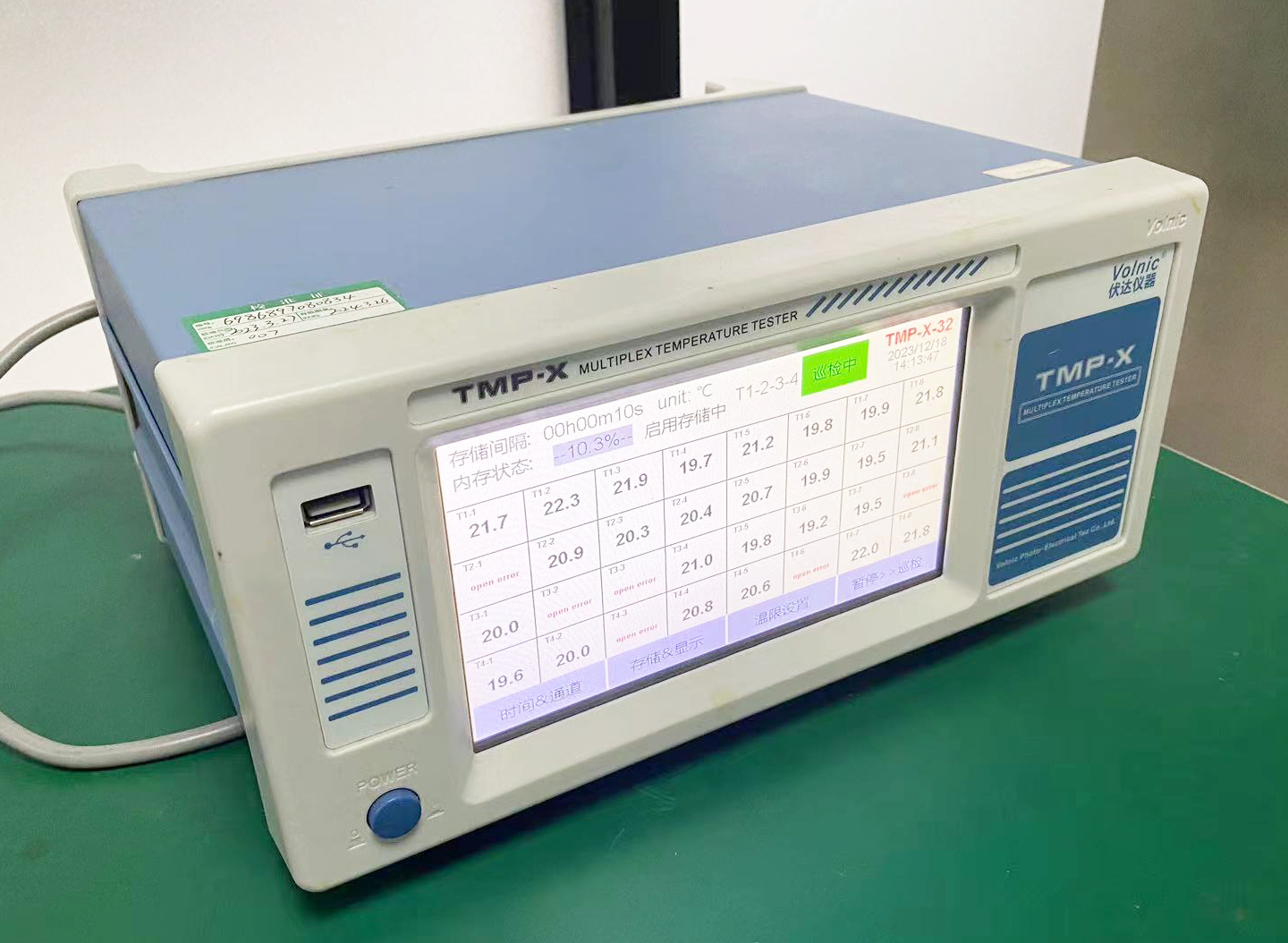

Temperature rise test

The temperature rise test is a method used to assess the heat generated by a device or system during operation.Details

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP