Tripath is a leading company that not only produces plastic parts according to customer requirements but also actively participates in the design process until the final production stage.

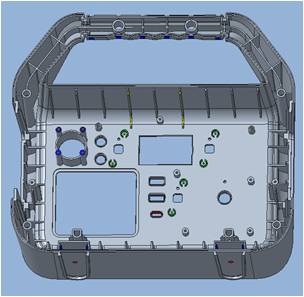

In a recent project, we were approached by a customer who needed plastic parts designed and manufactured for their portable power station and mobile phone wireless power bank. Throughout this project, we maintained close communication with the customer to discuss product functions and design details, ensuring that the final product would meet their expectations.

The portable power station has an impressive power reserve of up to 2 kWh, making it suitable for use with a wide range of electronic devices available on the market. Whether it's powering electric fans, stereos, drones, laptops, or even TVs. Additionally, we designed a mobile phone wireless power bank specifically tailored for devices with wireless charging capabilities. Its compact design and lightweight nature allow users to conveniently carry it wherever they go.

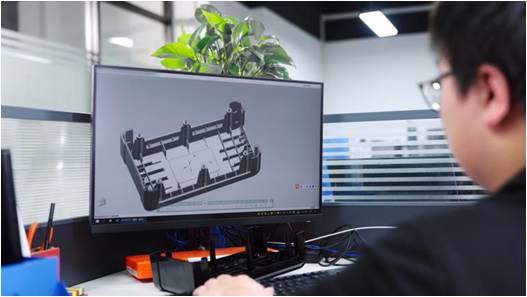

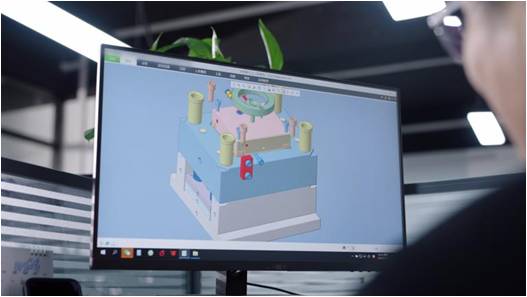

At Tripath, we possess our own mold design and manufacturing department, along with an injection molding workshop that consistently produces high-standard plastic parts. For this project, we utilized PC+ABS plastic injection molding technology.

This material boasts exceptional physical strength and UL V0 flame retardant performance, ensuring both the durability and safety of the final product. Furthermore, we have the capability to produce plastic parts in a variety of colors, matching the color numbers provided by customers and catering to their diverse needs.

If you require any further information or have additional inquiries, please do not hesitate to contact us. We are more than happy to assist you with your plastic part manufacturing needs.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP